Platings > Hard Gold Plating

Hard Gold Plating

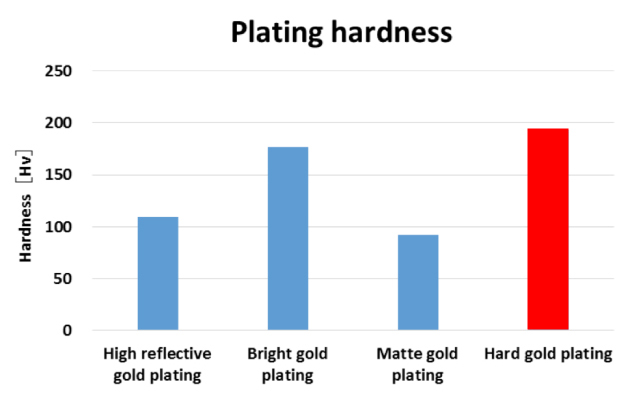

Our Hard Gold Plating is engineered for superior durability, achieving a high hardness range of HV190 to HV250, significantly surpassing conventional bright gold. This hardness is achieved by adding a small amount of hardener, specifically Cobalt (1-3%wt), to the deposit.

While the Cobalt additive slightly increases the contact resistance compared to pure or bright gold, our hard gold plating maintains an excellent overall performance profile:

・Superior Wear Resistance

・High Electrical Conductivity

・Excellent Soldering Characteristics

・Low Contact Resistance

Hard Gold Plating is the preferred choice for components that experience constant movement or friction and required a combination of hardness and conductivity.

Contact resistance of Bright gold and Hard gold are almost the same

Functional property

- Abrasion & Wear Resistance

- Low Contact Resistance

- Electrical Conductivity

Availability details

| mass production | yes |

|---|---|

| process type ※ | B,R,M |

| under plating | Ni |

| prototype | yes |

| experimental trial | yes |

| regular chemical stock | yes |

- ※

- B:barrelR:rackM:mesh basketH:reel to reel