Services > Analysis Service > Plating Property

Plating Property Analysis

Our evaluation instruments for the plating and finishing deposits property are picked up as follows. Due to these instruments, we can provide an advanced solution on plating and finishing.

Salt spray tester

The Salt spray tester is used for evaluating anti-corrosion quality by exposing the specimens to the salt mist. Our salt spray tester is applied to ASTM-B117, JIS-Z2371 and other international standard test method.

Constant temperature and humidity chamber

Test samples are set under a constant circumstance at the range of temperature -25 - 100 degree C, humidity 20 - 98%RH. This is one of the environmental testing to check whether the electronic components and devices have a resistance with the changes in ambient conditions.

Gas corrosion tester

This equipment is used for evaluating the corrosion resistance and discoloration of the samples. The samples are exposed to the corrosive gas such as SO2 and H2S.

Temperature cycling tester

By using temperature cycle tester, we can check the influence of temperature changes to the plating properties.

Solder wettability tester

This equipment is used for measuring the solder wettability quantitatively, which is called "wetting balance method”. Our plating deposits can be evaluated by IEC, JIS, and customer requiring specification.

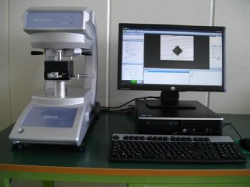

Microhardness tester

This tester is available for measuring Vickers and Knoop hardness. The diamond indenter is pushed into the sample, the hardness of the sample is determined from the amount of deformation. The Force applied to the indenter can be varied from 0.05gf to 2kgf.

Contact resistance measurement instrument

This instrument is used for measuring the conductivity of plating deposits and evaluating the anti-rust agent and lubricant.

The instrument performs the measurement of the surface resistance value by passing a current between the two probes loaded.

Sliding tester

As sliding the sample surface, we can measure the wear and the electrical properties continuously. A certain contact load and electrical load are set, and we continuously measure the frictional force and the contact resistance. Various contact materials, surface treatment, anti-rust coating and lubricant coating are able to be observed and measured.

Air atmosphere furnace

This furnace can increase the temperature up to around 900 degree C in an air atmosphere, it is used for the adhesion test or heat treatment of the product.

Reducing furnace (in hydrogen or nitrogen)

This furnace can increase the temperature up to around 1000 degree C in a deoxygenated atmosphere (hydrogen, nitrogen). Therefore it can be used for preventing from oxidation of the sample surface during a heating.

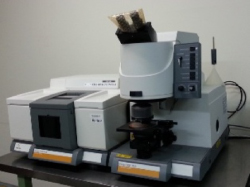

Fourier transform infrared spectrophotometer (FT-IR)

This equipment is used to analyze the organic matter.

By irradiating infrared rays on the material to be measured, and obtaining a spectrum of the transmission (or reflection) light,

it is possible to know the molecular structure and the state of the object.

We measure whole wavelength of the interfered light, and analyze the spectrums of transmitted or reflected light calculated by Fourier transform.

Because the microscopic system is included in this equipment, we can also measure the small area.

Bonding tester

This equipment is a bonding strength testing machine, we can make quantitative evaluation by a pull strength of the soldered pin.

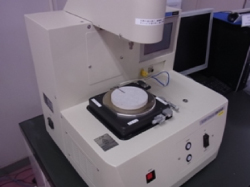

X-ray diffractometer (XRD)

This is used for observing the crystalline state of the metal. By using the diffraction phenomenon, the crystal structure of the material can be evaluated.

Pressure cooker tester

This equipment is used for evaluating the humidity resistance of the electronic components and materials in a saturated water vapor pressure at over 100 degree C.