About Us > Information > 2023-02-13

Platings in the Medical Field and Mitsuya's advantage

2023-02-13

Plating on parts used in medical equipment requires various characteristics due to the special environment of the equipment.

High reliability is required in terms of corrosion resistance, high strength, high reflection, non-magnetism, and high electrical conductivity.

In addition, the plating film must be biocompatible for devices that are directly attached to the human body.

Medical implants and wearables that come in contact with the human body need to be coated (plated) with metals that are bio-compatible meaning that they wont cause harm or an allergic reaction when in contact with the human skin.

Typical devices that need to a biocompatible plating are:

・ hearing aids

・ earbuds

・ smart watches

・ smart rings

・ implants

・ pacemakers

These devices are in direct contact with the human skin so they require coatings (plating, metallization) that do not have harmful allergic triggers.

Some harmful platings are listed below:

・ Nickel

・ Cobalt

・ Copper

・ Chromium

・ Mercury

These metals can cause skin reddening and itching.

However these metals have other good properties that are needed for electronic devices such as hardness, electrical conductivity, corrosion resistance etc.

Mitsuya for many years has recognized the need to develop platings that can be used to replace these metals in crucial areas for medical devices. With our years of experience and our highly qualified team of engineers and researchers we have developed the technology to apply difficult platings unto difficult substrates.

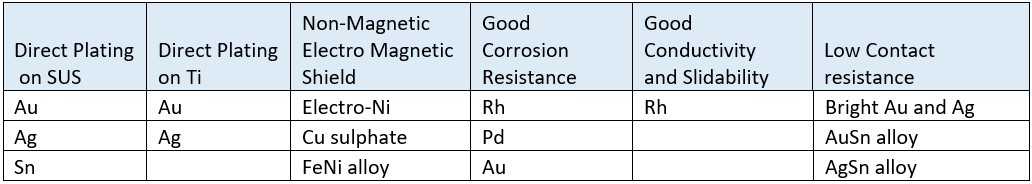

Our Technology

Direct plating on Stainless Steel

Nickel free platings (coating, metallization)

・ Au

・ Ag

・ Sn

Direct Plating on Ti

Nickel Free platings (coating, metallization)

・ Au

・ Ag

To replace nickel and cobalt we can offer Pd and Rh platings.

Pd plating Properties

・ Anti-corrosion

・ Abrasion and Wear Resistant

・ Hard Hv 200

・ Non-Magnetic

Rh plating offers

・ Brilliant reflective appearance and the appearance never changes.

・ Excellent wear and abrasion resistance.

・ Low electrical resistance.

・ Low and stable contact resistance.

・ High corrosion resistance.

・ High Surface Hardness Hv 800-1000

・ Lowest electrical resistance in the platinum metal group (Pd, Pd, Ru, Rh, Ir)

At Mitsuya we can create the best plating specifications for your needs. With 92 years of plating experience we have confidence that we can respond to all your plating needs. If you need advice on a difficult project then contact the plating experts and we will assist you to resolve that issue.

Contact us today.

※For Direct plating on Stainless steel an Ti other platings area available upon request and consultation.