Platings > Palladium-Nickel Alloy Plating

Palladium-Nickel Alloy Plating

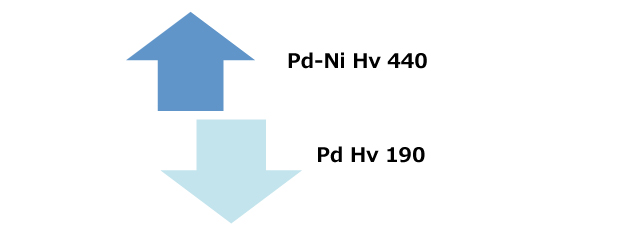

Mitsuya has developed an improved palladium-nickel alloy plating which has superior properties to pure palladium in the functions hardness and the wear resistance.

Palladium is inferior in corrosion resistance with activity chemically in the platinum group.

Palladium plating is somewhat dark tone, lacking in vividness. Because of this, it has been used as a base plating of rhodium-plating and gold-plating. Pure palladium is difficult to be plated thickly, too.

Mitsuya developed palladium-nickel alloy plating to make up for these weak points of the palladium plating. Depending on the ratio of nickel, corrosion resistance improves more than pure palladium plating, and the pinholes decrease. In addition, the hydrogen embrittlement is hard to occur.

The palladium-nickel alloy plating has higher hardness with Hv450 degree than pure palladium plating. Therefore it is often used for the point of contact part as an alternative plating to gold plating.

Recently, it has been widely used in the products that require sliding resistance and insertion resistance.

Mitsuya's Palladium-nickel alloy plating is able to plated by reel-to-reel, barrel, and rack.

Functional property

- Abrasion & Wear Resistance

- Corrosion Resistance

- Hardness

Industry employed

- High precision connectors

Availability details

| mass production | yes |

|---|---|

| process type ※ | R,H |

| under plating | Ni |

| prototype | yes |

| experimental trial | yes |

| regular chemical stock | yes |

- ※

- B:barrelR:rackM:mesh basketH:reel to reel